Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joints, are critical components in various civil engineering and construction applications. These seals are designed to provide watertight and structurally sound connections between concrete pipes, ensuring the integrity of sewage systems, stormwater drainage, and culvert structures. In this comprehensive description, we will delve into the world of concrete pipe seals, exploring their types, functions, materials, installation methods, benefits, and considerations.

1. Functions of Concrete Pipe Seals:

Concrete pipe seals serve several vital functions:

a. Watertightness: They create a secure, watertight seal between adjacent concrete pipes, preventing the leakage of sewage, stormwater, or other fluids from the pipe system.

b. Structural Integrity: Concrete pipe seals help distribute loads and maintain the structural integrity of the pipeline, ensuring it can withstand external pressures, traffic loads, and soil movement.

c. Protection Against Contamination: These seals prevent the intrusion of soil, debris, and contaminants into the pipe system, reducing the risk of blockages and maintaining water quality.

d. Sound Dampening: In some cases, concrete pipe seals can help reduce noise transmission through the pipe system, which is especially relevant in urban areas.

2. Types of Concrete Pipe Seals:

Several types of concrete pipe seals are available, each designed for specific applications:

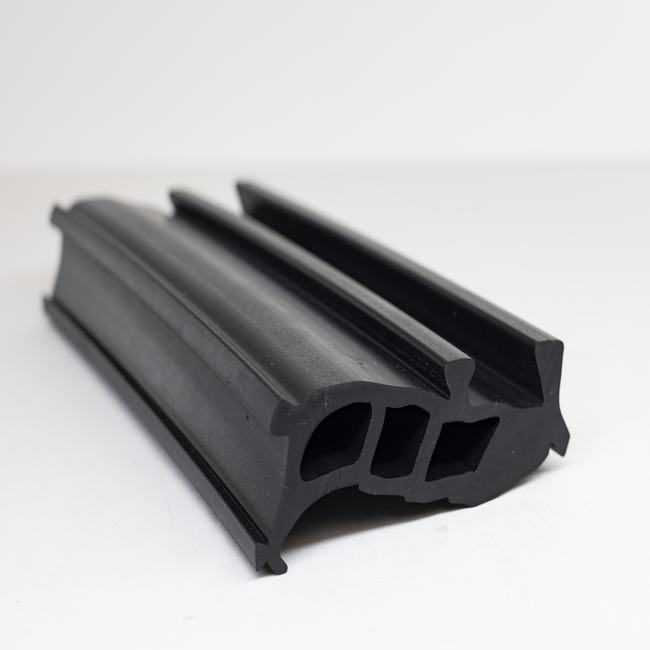

a. Rubber Ring Gaskets: These are the most common type of concrete pipe seals. They consist of rubber or elastomeric rings that fit into grooves on the spigot end of the concrete pipe. When the pipes are joined, the rubber gasket provides a watertight seal.

b. Mastic Seals: Mastic seals are adhesive compounds applied to the spigot end of the concrete pipe. When the pipes are connected, the mastic seal fills gaps and creates a seal.

c. Compression Seals: Compression seals use mechanical compression to form a seal. They typically involve a rubber gasket and a compression band that squeezes the gasket into place when the pipes are joined.

d. O-Ring Seals: O-ring seals use a circular rubber O-ring that fits around the spigot of one pipe and is compressed when joined with another pipe.

3. Installation Process:

The installation of concrete pipe seals involves the following steps:

a. Preparation: Ensure that the ends of the concrete pipes are clean, free of debris, and properly aligned.

b. Gasket Placement: If using rubber ring gaskets or O-ring seals, place the gasket on the spigot end of one pipe, ensuring it fits snugly.

c. Joining Pipes: Insert the spigot end of one pipe into the bell end of another pipe, ensuring the gasket or seal is correctly positioned.

d. Compression: If using compression seals, tighten the compression bands or fasteners to compress the gasket and create a seal.

e. Inspect and Test: After installation, visually inspect the joint to ensure proper alignment and sealing. Conduct pressure tests, if necessary, to verify the watertightness of the connection.

4. Benefits of Concrete Pipe Seals:

a. Reliability: Concrete pipe seals provide reliable and durable connections that can withstand the test of time and environmental factors.

b. Watertightness: They ensure a watertight seal, preventing leaks and preserving water quality.

c. Structural Integrity: Concrete pipe seals contribute to the structural stability of the pipeline, making it capable of handling heavy loads and external pressures.

d. Ease of Installation: Installation is typically straightforward, reducing labor and time requirements.

e. Versatility: Concrete pipe seals can be used in various pipe sizes and types, accommodating different project needs.

5. Considerations:

a. Material Compatibility: Ensure that the seals are compatible with the materials used in the concrete pipes and any chemicals present in the conveyed fluids.

b. Quality Assurance: Use high-quality seals to ensure long-term performance and reliability.

c. Installation Training: Proper installation techniques are crucial for effective sealing, so personnel should be trained accordingly.

d. Environmental Conditions: Consider factors such as temperature variations and soil conditions that may affect the performance of the seals over time.

In summary, concrete pipe seals are essential components for creating secure, watertight, and structurally sound connections in various civil engineering and construction applications. Their ability to maintain pipeline integrity, prevent contamination, and provide a reliable seal makes them indispensable for the efficient functioning of sewage systems, stormwater drainage, and culvert structures. Careful selection, proper installation, and regular maintenance are vital to ensuring the longevity and effectiveness of concrete pipe seals in any infrastructure project.